Design Curve Calculations for Sample. 'Simple Ejector Design Parameters,' by P. Mar 23, 2012 - of a compressible fluid ejector used in particular in sugar refineries for. Ez loader boat trailer serial number location. Nikon picture control preset. Conditioning, and in a complementary study 6 they investigated an ejector design using a.

Air Ejector Design

- This means that if you dont correctly design/select the optimum size/model in your sizing calculation, you will end up with wrong results (basically high or low motive gas flow rate). In your case, you have used very large ejector for your application, that is why you need a high flow rate of motive gas in order to establish the required.

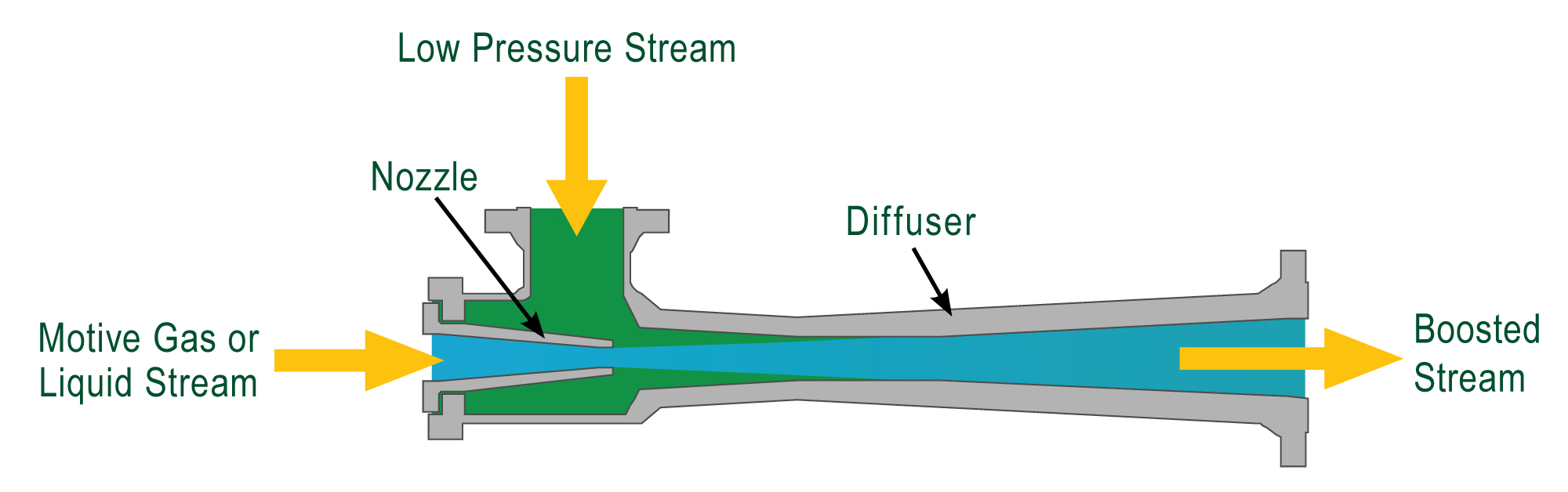

- An ejector is a device used to suck the gas or vapour from the desired vessel or system. An ejector is similar to a vacuum pump or compressor. The major difference between the ejector and vacuum pump or compressor is it had no moving parts. Hence it is relatively low-cost and easy to operate and maintenance-free equipment. Ejector Working Principle.

Eductor calculations

Eductor calculations

Liquid Ejector Design Calculation

Steam Ejector Design

Anyone have experience with eductors?

I am a new engineer and am looking for pointers on calculating the flowrate needed to move a gas.

We have up to a 150# steam supply as the motive stream. The question is what pressure can we regulate this steam to in order to still maintain the flow.

We are passing the steam at some pressure (this is what is to be determined) through the eductor to induce the flow of a stack gas, which is at or near atmospheric pressure (may actually be a slight vacuum). The outlet of the eductor will have a stack gas/steam mixture that will then be returned to the stack. This flow will serve as a 'fast loop' that every so often an analyzer will pull a 'slip stream' from to test.

Any suggestions as to how to formulate a relation of motive stream to outlet pressure? The eductor used for gases is basically a converging/diverging nozzle from what I understand. The pressure of the motive stream is dropped, to increase its velocity. This in turn sucks the stack gas into the eductor. The two then exit the eductor at an intermediate pressure.

Also, any good sites that thoroughly explain steam usage in refineries? I am looking for something that starts with the basics of steam.

Thank you..

I am a new engineer and am looking for pointers on calculating the flowrate needed to move a gas.

We have up to a 150# steam supply as the motive stream. The question is what pressure can we regulate this steam to in order to still maintain the flow.

We are passing the steam at some pressure (this is what is to be determined) through the eductor to induce the flow of a stack gas, which is at or near atmospheric pressure (may actually be a slight vacuum). The outlet of the eductor will have a stack gas/steam mixture that will then be returned to the stack. This flow will serve as a 'fast loop' that every so often an analyzer will pull a 'slip stream' from to test.

Any suggestions as to how to formulate a relation of motive stream to outlet pressure? The eductor used for gases is basically a converging/diverging nozzle from what I understand. The pressure of the motive stream is dropped, to increase its velocity. This in turn sucks the stack gas into the eductor. The two then exit the eductor at an intermediate pressure.

Also, any good sites that thoroughly explain steam usage in refineries? I am looking for something that starts with the basics of steam.

Thank you..